For over three decades, our team at Precision Engineering has been delivering high-quality custom metal fabricated solutions to original equipment manufacturers (OEMs) in various sectors – from aerospace/defense to medical device to power systems to security & fire suppression systems and other critical manufacturing industries.

How can we help you find solutions to your unique challenges?

Following are examples of ways we’ve worked with our customers to fabricate flexible and customized solutions – forming results for them.

The Problem

Our representatives were approached by a global defense contractor searching for a new manufacturing partner. Their current supplier was undergoing a corporate restructuring and would no longer be manufacturing the customer’s critical components.

The required components were complex and exacting in tolerance requirements, and the current supplier had also had some quality-related issues – requiring rework on the customer’s end.

The client needed a new, flexible manufacturing partner who could quickly and reliably meet demand and requirements.

THE SOLUTION

Working closely with the client, our technical and administrative professionals developed and qualified a manufacturing process to seamlessly transition production to our facilities.

Our advanced CNC laser/punch machines allow us to perform all manufacturing steps in one operation; and to perform more advanced inspections and measurements, we also purchased advanced laser QC scanning equipment.

THE OUTCOME

Precision Engineering was able to quickly partner with this client and remove the burden of production delays and quality-related rework.

We continue to work closely with the customer on manufacturing a variety of their

components – including working closely with the customer on acquiring the necessary raw materials, which are often quite costly.

The Problem

We were approached by a current customer regarding the manufacture of custom industrial tanks, in varying dimensions. Their foreign-based supplier couldn’t meet their demand – on both delivery and quality. Rework and delivery delays were costing the customer large amounts of money and headaches. The customer wanted a new manufacturing partner for this project, who could deliver high-quality product, when needed and at a cost-effective price.

THE SOLUTION

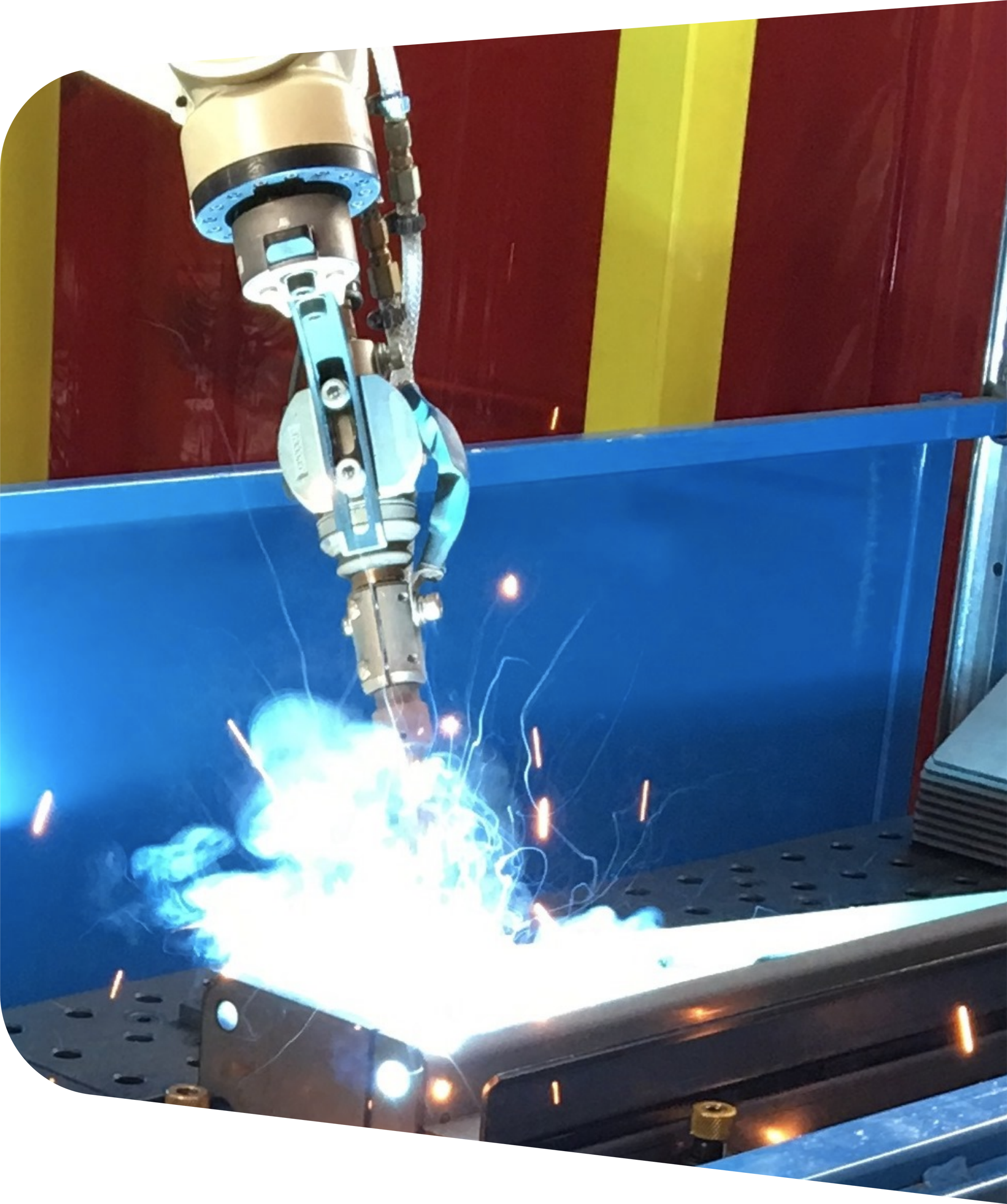

At the time, we didn’t have all the necessary equipment to optimize the manufacture of this product. However, we consider ourselves partners with our customers, and we wanted to find a win/win solution.

So, our experts researched the feasibility of purchasing the necessary equipment to handle the project’s demands; and working with a robot integrator, we installed a custom robotic welding cell and created a specialized testing station. As the new equipment came online, we continued making the system applicable for other customers’ projects.

THE OUTCOME

Working closely with the customer to “develop and qualify” the manufacturing process, we’ve removed the customer’s burden of delays, reworks, and other cost overruns – delivering a reliable high-quality product, on time and at a cost-effective price (with the added benefit of manufacturing these parts domestically).

…and at a showcase for their executive management, this project was highlighted.

The Problem

A new client, in need of a complicated electrical enclosure, contacted us because they required a new supplier. They were very unhappy with their current supplier; and to add to the problem of substandard work, the current supplier had no documentation from which a new supplier could develop a manufacturing process.

They urgently needed a new manufacturing partner who could pick up on the existing work and reliably deliver a product that met their quality requirements.

THE SOLUTION

Our technical professionals requested and received a sample of the existing product.

Despite the complexity of the project, the existing product’s quality problems, and having no blueprint or specification documentation, we were able to reverse-engineer the product, create a manufacturing process, and produce a superior product, to meet the customer’s needs and requirements.

THE OUTCOME

We have been able to reliably meet the customer’s quality and delivery requirements, producing a high-quality part from raw material to a powder-coated finished enclosure, at a cost-effective price with proper documentation.

Why Precision Engineering LLC?

Whatever your unique manufacturing challenge, our team at Precision Engineering is ready and able to meet your complex needs.

With a motto of “Fabricating Solutions, Forming Results,” we’re your partner in manufacturing your final product. The work we do is important – it’s important to you and it’s important to us.

Contact us at info@precisionengineering.com

Or call 508-278-5700

To find out how we can help you today.